Hyundai i-30: Front Suspension System / Sub Frame

Repair procedures

| Removal |

| 1. |

Loosen the wheel nuts slightly.

Raise the vehicle, and make sure it is securelysupported.

|

| 2. |

Remove the front wheel and tire (A) from the fronthub.

|

| 3. |

Disconnect the stabilizer link with the front strutassembly after loosening

the nut (A).

|

| 4. |

Remove the tie rod end ball joint.

|

| 5. |

Loosen the lower arm nut (A) and then remove thelower arm ball joint

by using SST (09568-1S100).

|

| 6. |

Loosen the bolt (A) and then disconnect the universaljoint assembly

from the pinion of the steering gearbox.

|

| 7. |

Remove the roll rod stopper (A) by loosening the boltand nut.

|

| 8. |

Remove the muffler rubber hanger (A).

|

| 9. |

Remove the heat protector (A).

|

| 10. |

Remove the subframe by loosening the mountingbolts and nuts.

|

| 11. |

Loosen the mounting bolts and then remove thestabilizer bar (A).

|

| 12. |

Remove the protector (A), (B) and (C).

[RHD]

[LHD]

|

| 13. |

Remove the steering gearbox (A) by loosening themounting bolts.

[LHD]

[RHD]

|

| 14. |

Remove the front lower arm after loosening the bolts& nuts.

|

| 15. |

To install, reverse the removal procedure.

|

| 16. |

Check the front alignment.

(Refer to Suspension System - "Front Alignment")

|

Front Stabilizer Bar

Front Stabilizer Bar

Repair procedures

Removal

1.

Loosen the wheel nuts slightly.

Raise the vehicle, and make sure it is securely supported...

Other information:

Hyundai i30 (PD) 2018-2025 Service Manual: Smart Key

Repair procedures Smart Key Smart Key Code Saving 1. Connect the DLC cable of GDS to the data link connector (16 pins) in driver side crash pad lower panel, turn the power on GDS. 2...

Hyundai i30 (PD) 2018-2025 Owner's Manual: Securing a Child Restraint System seat with “Top-tether Anchorage” system

Top-tether anchorages for Child Restraint Systems are located on the rear of the seatbacks. 1. Route the Child Restraint System top-tether strap over the seatback. Placing the top tether strap, please follow the instructions of the Child Restraint System manufacturer...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Theft-alarm system

- Battery replacement

- Tyre pressure monitoring system

- New on site

- Most important about car

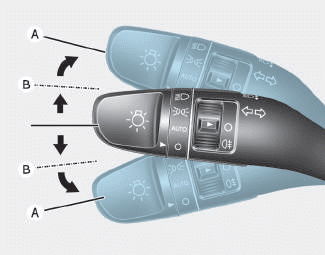

Turn signals and lane change signals

To signal a turn, push down on the lever for a left turn or up for a right turn in position (A). To signal a lane change, move the turn signal lever slightly and hold it in position (B).The lever will return to the OFF position when released or when the turn is completed.

Copyright © 2025 www.hi30.net