Hyundai i-30: Rear Wiper/Washer / Rear Wiper Motor

Hyundai i30 (PD) 2018-2025 Service Manual / Body Electrical System / Rear Wiper/Washer / Rear Wiper Motor

Repair procedures

| Inspection |

Rear Wiper Motor

| 1. |

Remove the connector from the rear wiper motor.

|

| 2. |

Connect positive (+) battery cables to terminal 4 and negative (-) battery

cables to terminal 3 respectively.

|

| 3. |

Check that the motor operates normally. If they are abnormal, replace

the washer motor.

|

Automatic Stop Operation Check

| 1. |

Operate the motor at low speed using the stalk control.

|

| 2. |

Stop the motor operation anywhere except at the off position by disconnecting

the motor connector.

|

| 3. |

Connect the positive (+) lead from the battery to terminal 1 and the

negative (-) lead to terminal 3.

|

| 4. |

Connect the motor terminal 2 and terminal 4.

|

| 5. |

Check that the motor stops running at the off position.

|

| Inspection (With GDS) |

| 1. |

In the body electrical system, failure can be quickly diagnosed by using

the vehicle diagnostic system (GDS).

The diagnostic system(GDS) provides the following information.

|

| 2. |

Select the 'Car model' and the 'Body Control Module (BCM)' to be checked

in order to check the vehicle with the tester.

|

| 3. |

Select the 'Current Data' menu to search the current state of the input/output

data.

|

| Removal |

| 1. |

Remove the rear wiper arm & blade (B) after removing the nut and detaching

the wiper cap (A).

|

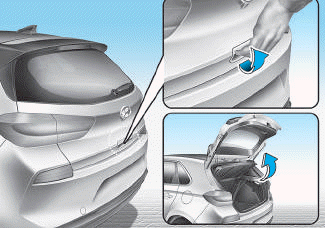

| 2. |

Remove the tailgate trim after opening the tailgate.

(Refer to Body - "Tailgate Trim")

|

| 3. |

Disconnect the rear wiper motor connector (A) and then remove the rear

wiper motor (B) after loosening bolts (3EA).

|

| Installation |

| 1. |

Install the rear wiper motor assembly.

|

| 2. |

Install the tailgate trim.

|

| 3. |

Install the rear wiper arm and rear wiper cap.

|

| 4. |

Set the rear wiper blade and to the lowest defogger heat line and tailgate

glass.

|

Components and components location

Components and components location

Component Location

1. Rear wiper

arm & blade

2. Rear wiper arm nut

3. Rear wiper grommet

4. Rear wiper

motor assembly

5...

Rear Washer Switch

Rear Washer Switch

Repair procedures

Inspection

Multifunction Switch Inspection

1.

Check for continuity between the terminals in each switch position as

shown below...

Other information:

Hyundai i30 (PD) 2018-2025 Owner's Manual: Where are the air bags?

Driver’s and passenger’s front air bags Your vehicle is equipped with a Supplemental Restraint System (SRS) and lap/shoulder belts at both the driver and passenger seating positions. The SRS consists of air bags which are located in the centre of the steering wheel, in the driver’s side lower crash pad below the steering wheel, and the passenger's side front panel pad above the glove box...

Hyundai i30 (PD) 2018-2025 Owner's Manual: Reverse parking aid function

When you move the shift lever to the R (Reverse) position, the outside rearview mirror(s) will rotate downwards to aid with driving in reverse. The position of the outside rearview mirror switch (1) determines whether or not the mirrors will move: Left/Right : When either the L (Left) or R (Right) switch is selected, both outside rearview mirrors will move...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Tyre pressure monitoring system

- Brake/clutch fluid

- Drive mode integrated control system

- New on site

- Most important about car

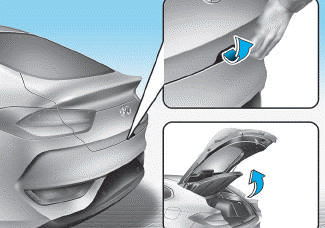

Tailgate

Opening the tailgate

■ 5 Door, Wagon

■ Fastback

Copyright © 2025 www.hi30.net