Hyundai i-30: Maintenance / Explanation of scheduled maintenance items

Engine oil and filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the vehicle is being driven in severe conditions, more frequent oil and filter changes are required.

Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked periodically for proper tension and adjusted as necessary.

CAUTION

When you are inspecting the belt, place the ignition switch to the LOCK/OFF or ACC position.

Fuel filter (cartridge)

A clogged-up fuel filter may limit the vehicle driving speed, damage the emission system, and cause the hard starting. When a considerable amount of foreign substances are accumulated in the fuel tank, the fuel filter should be replaced.

Upon installing a new fuel filter, operate the diesel engine for several minutes, and check the connections for any leakages.We recommend you to have the fuel filter replaced by a HYUNDAI authorised repairer.

Fuel lines, fuel hoses and connections

Check the fuel lines, fuel hoses and connections for leakage and damage. We recommend that the fuel lines, fuel hoses and connections be replaced by a HYUNDAI authorised repairer.

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance schedule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessive swelling indicate deterioration. Particular attention should be paid to examine those hose surfaces nearest to high heat sources, such as the exhaust manifold.

Inspect the hose routing to ensure that the hoses do not come in contact with any heat source, sharp edges or moving component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence of deterioration or damage.

Air cleaner filter

We recommend that the air cleaner filter be replaced by a HYUNDAI authorised repairer.

Spark plugs (for Petrol Engine)

Make sure to install new spark plugs of the correct heat range.

WARNING

Do not disconnect and inspect spark plugs when the engine is hot.You may burn yourself.

Valve clearance (for Petrol Engine)

Inspect excessive valve noise and/or engine vibration and adjust if necessary. We recommend that the system be serviced by a HYUNDAI authorised repairer.

Cooling system

Check the cooling system parts, such as radiator, coolant reservoir, hoses and connections for leakage and damage. Replace any damaged parts.

Engine coolant

The coolant should be changed at the intervals specified in the maintenance schedule.

Automatic transmission fluid (if equipped)

Automatic transmission fluid should not be checked under normal usage conditions.

We recommend that the automatic transmission fluid is changed by a HYUNDAI authorised repairer according to the maintenance schedule.

Information

Automatic transmission fluid colour is red when new.

As the vehicle is driven, the automatic transmission fluid will begin to look darker.

This is a normal condition. It does not need to be replaced based on the colour change.

NOTICE

The use of a non-specified fluid could result in transmission malfunction and failure.

Use only specified automatic transmission fluid.

Manual transmission fluid

Inspect the manual transmission fluid according to the maintenance schedule.

Dual clutch transmission fluid (if equipped)

Inspect the dual clutch transmission fluid according to the maintenance schedule.

Brake hoses and lines

Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately.

Brake/Clutch fluid (if equipped)

Check the brake/clutch fluid level in the brake fluid reservoir. The level should be between “MIN” and “MAX” marks on the side of the reservoir. Use only hydraulic brake fluid conforming to DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system including the parking brake lever and cables.

Brake pads, calipers and rotors

Check the pads for excessive wear, discs for run out and wear, and calipers for fluid leakage. For more information on checking the pads or lining wear limit, refer to the HYUNDAI web site. (http://service.hyundai-motor.com)

Suspension mounting bolts

Check the suspension connections for looseness or damage. Retighten to the specified torque.

Steering gear rack, linkage & boots/lower arm ball joint

With the vehicle stopped and engine off, check for excessive free-play in the steering wheel.

Check the linkage for bends or damage. Check the dust boots and ball joints for deterioration, cracks, or damage. Replace any damaged parts.

Drive shafts and boots

Check the drive shafts, boots and clamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease.

Air conditioning refrigerant/ compressor

Check the air conditioning lines and connections for leakage and damage.

Scheduled maintenance services

Scheduled maintenance services

Follow Normal Maintenance Schedule if the vehicle is usually operated where

none of the following conditions apply.

If any of the following conditions apply, you must follow the Maintenance Under

Severe Usage Conditions...

Engine oil

Engine oil

Checking the engine oil level

1. Be sure the vehicle is on level

ground.

2. Start the engine and allow it to reach

normal operating temperature...

Other information:

Hyundai i30 (PD) 2018-2025 Owner's Manual: Parking Distance Warning (Reverse/Forward) system

The Parking Distance Warning (Reverse/Forward) system assists the driver during movement of the vehicle by chiming if any object is sensed within the distance of 100 cm (39 inches) in front and 120 cm (47 inches) behind the vehicle. This system is a supplemental system that senses objects within the range and location of the sensors, it cannot detect objects in other areas where sensors are not installed...

Hyundai i30 (PD) 2018-2025 Owner's Manual: Power adjustment

WARNING NEVER allow children in the 2 vehicle unattended. The power seats are operable when the engine is turned off. NOTICE To prevent damage to the seats: Always stop adjusting the seats when the seat has been adjusted as far forward or rearward as possible...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Exhaust System (DPF) Warning Light. Glow Indicator Light

- Theft-alarm system

- To activate the ISG system

- New on site

- Most important about car

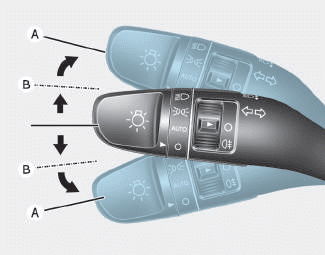

Turn signals and lane change signals

To signal a turn, push down on the lever for a left turn or up for a right turn in position (A). To signal a lane change, move the turn signal lever slightly and hold it in position (B).The lever will return to the OFF position when released or when the turn is completed.