Hyundai i-30: Tires/Wheels / Alignment

Repair procedures

| Front wheel alignment |

|

Toe

|

B - A > 0 : Toe in (+)

B - A < 0 : Toe out (-)

|

Toe adjustment

| 1. |

Loosen the tie rod end lock nut.

|

| 2. |

Remove the bellows clip to prevent the bellows from being twisted.

|

| 3. |

Adjust the toe by screwing or unscrewing the tie rod. Toe adjustment

should be made by turning the right and left tie rods by the same amount.

|

| 4. |

When completing the toe adjustment, install the bellows clip and tighten

the tie rod end lock nut to specified torque.

|

Camber and Caster

Camber and Caster are pre-set at the factory, so they do not need to be adjusted.

If the camber and caster are not within the standard value, replace or repair

the damaged parts and then inspect again.

|

Item |

Specification |

|

|

Camber angle |

Europe |

-0.5° ± 0.5° |

|

Russia |

-0.4° ± 0.5° |

|

|

Caster angle : 6.4° ± 0.5°

|

King-pin angle

|

King-pin : 14.5° ± 0.5°

|

|

| Rear wheel alignment |

When using a commercially available computerized wheel alignment equipment

to inspect the rear wheel alignment, always position the vehicle on

a level surface.

Prior to inspection, make sure that the rear suspension system is in

normal operating condition and that the tires are inflated to the specified

pressure.

|

Toe

|

B - A > 0 : Toe in (+)

B - A < 0 : Toe out (-)

|

Toe adjustment

|

Item |

Specification |

|

|

Toe-in |

Total |

0.14° ± 0.2° |

|

Individual |

0.07° ± 0.1° |

|

| 1. |

Adjust rear toe by turning the rear assist arm cam bolt (A) clockwise

or counter clockwise. Toe adjustment should be made by turning the right

and left cam bolt by the same amount.

|

| 2. |

When completing the toe adjustment, tighten the nut to specified torque.

|

Camber Adjustment

| 1. |

Loosen the nut holding the rear lower arm cam bolt (B).

|

| 2. |

Adjust rear camber by turning the rear lower arm cam bolt (B) clockwise

or counter clockwise. Rear camber adjustment should be made by turning

the right and left cam bolt by the same amount.

|

| 3. |

When completing the rear camber adjustment, tighten the nut to specified

torque.

|

Wheel

Wheel

Repair procedures

Hub nut tightening sequence

1.

Tighten the hub nuts as follows.

Tightening torque :

107...

Tire Pressure Monitoring System

Tire Pressure Monitoring System

Description and operation

Description

Indirect Tire Pressure Monitoring System (TPMS)

Using a wheel speed signal from the ESC, the system analyzes the turning radius

of the tire and change in tire stiffness to detect a pressure loss...

Other information:

Hyundai i30 (PD) 2018-2025 Service Manual: Front Door Window Glass

Components and components location Component Location 1. Front door window glass Repair procedures Replacement 1. Remove the front door trim. (Refer to Front Door - "Front Door Trim") 2...

Hyundai i30 (PD) 2018-2025 Owner's Manual: Cigarette lighter

■ Type A ■ Type B To use the cigarette lighter, the ignition switch must be in the ACC or ON position. Push the cigarette lighter all the way into its socket. When the element is heated, the lighter will pop out to the “ready” position...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Tyre pressure monitoring system

- Battery replacement

- Theft-alarm system

- New on site

- Most important about car

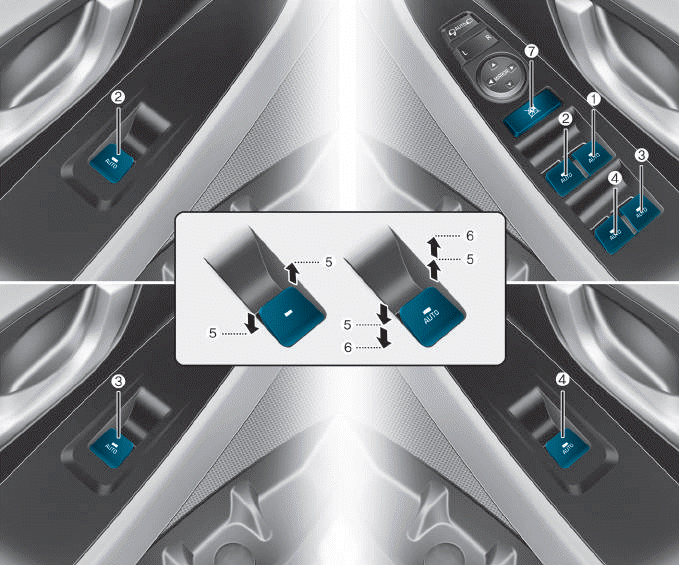

Power windows

(1) Driver’s door power window

switch

(2) Front passenger’s door power

window switch

(3) Rear door (right) power window

switch

(4) Rear door (left) power window

switch

(5) Window opening and closing

(6) Automatic power window

(7) Power window lock switch

Copyright © 2025 www.hi30.net