Hyundai i-30: Cylinder Head Assembly / CVVT & Camshaft

Hyundai i30 (PD) 2018-2025 Service Manual / Engine Mechanical System / Cylinder Head Assembly / CVVT & Camshaft

Description and operation

| Description |

The continuous variable valve timing (CVVT) system advances or retards the opening

of an intake or exhaust valve according to the ECM signals that are determined

based on engine RPM and load.

Due to CVVT control, a valve overlap or underlap occurs between the intake valve

and exhaust valve, resulting in the reduction of pumping loss, recirculation

of exhaust gas, improvement in combustion stability and volumetric efficiency,

and increase in expansion work. This in turn improves fuel efficiency and engine

performance and reduces emission gases (NOx and HC).

The CVVT system is composed of a CVVT oil control valve (OCV), CVVT oil temperature

sensor (OTS), and a cam phaser; The OCV receives a pulse width modulation signal

from the ECM and controls the flow of oil to supply oil to the cam phaser, the

OTS measures the temperature of the engine oil, and the cam phaser changes the

phase of the camshaft using the engine oil pressure.

The oil supplied from the CVVT OCV rotates the rotor connected to the camshaft

inside the cam phaser. The rotor, in turn, rotates the camshaft in the direction

of engine rotation (intake advanced / exhaust retarded) or in the opposite direction

of engine rotation (intake retarded / exhaust advanced) to change the phase

angle of the cam.

| Operation Principle |

The CVVT has the mechanism rotating the rotor vane with hydraulic force generated

by the engine oil supplied to the advance or retard chamber in accordance with

the CVVT oil control valve control.

|

| 1. |

Intake CVVT

|

| 2. |

Exhaust CVVT

|

| [CVVT System Mode] |

|

(1) Low Speed / Low Load |

(2) Part Load |

|

|

|

|

(3) Low Speed / High Load |

(4) High Speed / High Load |

|

|

|

|

Driving Condition |

Exhaust Valve |

Intake Valve |

||

|

Valve Timing |

Effect |

Valve Timing |

Effect |

|

|

(1) Low Speed /Low Load |

Completely Advance |

* Valve Under-lap * Improvement of combustion stability |

Middle |

* Valve Under-lap * Improvement of combustion stability |

|

(2) Part Load |

Retard |

* Reduction of HC |

Retard |

* Delays the closing time of intake valve to reduce pumping loss |

|

(3) Low Speed /High Load |

Completely Advance |

* Reduction of pumping loss |

Advance |

* Improvement of volumetric efficiency |

|

(4) High Speed /High Load |

Completely Advance |

* Reduction of pumping loss |

Advance |

* Improvement of volumetric efficiency |

Repair procedures

| Removal |

|

|

| 1. |

Remove the cylinder head cover.

(Refer to Cylinder Head Assembly - "Cylinder Head Cover")

|

| 2. |

Turn the crankshaft damper pulley and align its groove with the timing

mark of the timing chain cover to set the piston of No.1 cylinder to

the top dead center on compression stroke.

|

| 3. |

Remove the timing chain cover.

(Refer to Timing System - "Timing Chain Cover")

|

| 4. |

Before removing the timing chain, mark the timing chain with an identification

based on the location of the sprocket (CVVT) because the identification

mark on the chain for TDC (Top Dead Center) can be erased.

|

| 5. |

Remove the timing chain.

(Refer to Timing System - "Timing Chain")

|

| 6. |

Remove the intake CVVT assembly (A) and exhaust CVVT assembly (B).

|

| 7. |

Remove the front camshaft bearing cap (A) and the camshaft bearing caps

(B).

|

| 8. |

Remove the CVVD assembly.

Use the CVVD fixture

Do not use the CVVD fixture

|

| 9. |

Remove the exhaust camshaft (A).

|

| Inspection |

Camshaft

| 1. |

Inspect the cam lobes.

Using a micrometer, measure the cam lobe height.

If the cam lobe height is less than standard, replace the camshaft.

|

| 2. |

Check the surface of the camshaft journal for wear.

If the journal is worn excessively, replace the camshaft.

|

| 3. |

Inspect the camshaft journal clearance.

|

| 4. |

Inspect the camshaft end play.

|

| Installation |

| 1. |

Install the exhaust camshaft (A).

|

| 2. |

Install the CVVD assembly (A).

|

| 3. |

Install the intake CVVT assembly (A) and exhaust CVVT assembly (B).

|

| 4. |

Install the front camshaft bearing cap and the camshaft bearing caps

as following method with specified torque.

|

| 5. |

Install the other parts in the reverse order of removal.

|

Cylinder Head Cover

Cylinder Head Cover

Components and components location

Components

1. Cylinder head

cover

2. Engine oil cap

3. Cylider head cover gasket

4...

CVVD Assembly

CVVD Assembly

Description and operation

Description

CVVD (Continuous Variable Valve Duration) System is a device to control the

optimum open and close timing according to the driving mode by changing the

valve opening section...

Other information:

Hyundai i30 (PD) 2018-2025 Service Manual: Front Fog Lamps

Repair procedures Removal Daytime Running Light (DRL) 1. Disconnect the negative (-) battery terminal. 2. Remove the front bumper. (Refer to Body - "Front Bumper Cover") 3...

Hyundai i30 (PD) 2018-2025 Owner's Manual: Engine compartment

1. Engine coolant reservoir/ Engine coolant cap 2.Brake/clutch fluid reservoir 3. Air cleaner 4. Engine oil dipstick 5. Engine oil filler cap 6.Windscreen washer fluid reservoir 7.Fuse box 8. Battery 1. Engine coolant reservoir 2...

Categories

- Manuals Home

- 3rd Generation i30 Owners Manual

- 3rd Generation i30 Service Manual

- Brake/clutch fluid

- EPB malfunction indicator

- Engine compartment

- New on site

- Most important about car

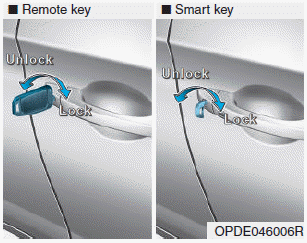

Door locks

Operating door locks from outside the vehicle

Mechanical key

Turn the key toward the rear of the vehicle to unlock and toward the front of the vehicle to lock.

If you lock/unlock the driver's door with a key, a driver’s door will lock/unlock automatically.

Copyright © 2025 www.hi30.net